Dura-Bar® Continuous Cast Iron Available from Industrial Tube and Steel

Industrial Tube and Steel offers Dura-Bar® Continuous Cast Iron products available in:

- Grades of Gray Iron (G2, G2P, GX) and Ductile Iron (65-45-12, 80-55-06, 100-70-02, SSDI)

- Solid rounds ranging from 1.25" to 26.56” in diameter

- Tubing available in Gray Iron G2 and Ductile Iron with sizes from 3.5” OD x 1.5” ID to 9” OD x 7” ID.

- Squares, rectangles and plate stock available in Gray and Ductile grades

- 72” nominal lengths (varies depending on diameter). Also available in 144" lengths.

- Available in as-cast, milled, or turned/ground surface finishes.

- Dura-Bar Iron Stock Allowances

Dura-Bar® is the world leader in the production, technology and application of continuous cast iron bar stock.

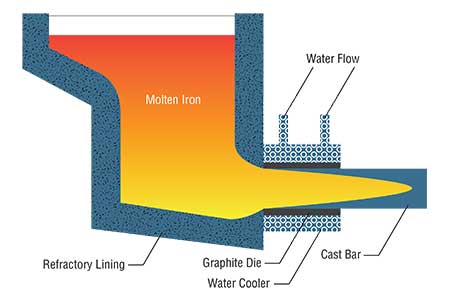

Industrial Tube and Steel is a leading supplier of Dura-Bar® continuous cast iron, which offers similar properties to steel but with higher quality machining, better thermal conductivity, and a reduced cost to comparable steel products. Dura-Bar® is available in a wide variety of sizes and shapes in all the standard ASTM A48 and ASTM A536 gray and ductile iron grades. Dura-Bar® gray iron bar stock is a good alternative to iron castings because of its high quality, consistent machinability, and dense fine-grained microstructure, which produces excellent surface finishes. Dura-Bar® ductile iron is highly machinable, making it a superior alternative to carbon steel bars. There are many advantages of Dura-Bar®. With Dura-Bar, there are no defects like those typically found in castings – e.g., porosity, slag, hard spots, shrinkage, etc. Dura-Bar's material consistency stems from the continuous casting process used to produce it. Continuous casting involves pulling bars through a graphite die at the bottom of a crucible filled with molten iron. Dross, slag, and other impurities float to the top of the crucible and never make it into the cast bars. Besides eliminating defects, continuous casting also yields an especially fine-grained microstructure which permits faster machining and extended tool life. This boosts throughput and lowers a manufacturer's cost per part. It also permits better surface finishes.

Dura-Bar's® Continuous Casting Process

The dura-Bar's® continuous casting process begins with water-cooled graphite die that is machined to form the shape of the bar.

The die is mounted on a bar machine crucible. As the bar is pulled horizontally from the crucible, the head pressure feeds molten iron into the die, producing a fine-grained cast iron bar.

Since the bar is being pulled from the bottom of the holding crucible, dross, slag, and other impurities float to the top, away from the opening of the die. The Dura-Bar® process enables the microstructure to be free from shrinkage, gas holes, and other tool-wearing inclusions.

Benefits of Dura-Bar® Continuous Cast Iron

Dura-Bar® continuous cast iron provides unparalleled value for any manufacturer needing an efficient metal for the production of their machined component parts. Dura-Bar® provides numerous physical and structural advantages over steel, castings, and aluminum because of the unique manufacturing process. Below are the principal benefits you can expect from Dura-Bar® Continuous Cast Iron:

Corrosion resistance is not a specific property of metal but a characteristic that depends on the conditions of exposure and the quality of performance that is required. All Dura-Bar® irons have two constituents in their microstructure, graphite, and matrix structure. Graphite will withstand a wide variety of chemical and atmospheric conditions and the matrix structure will behave similarly to non-alloyed steel under the same conditions.

Dura-Bar® Ni-Resist, having an austenitic matrix, is the most corrosion-resistant grade, although even standard grades of Dura-Bar® may be suitable depending on the environment. Selection of the proper grade depends on the application. Each case should be reviewed independently.

Fatigue strength is primarily influenced by the graphite size and shape and will also be affected by the matrix structure. The Dura-Bar® continuous casting process and strict metallurgical controls result in a uniformly dense, fine-grained microstructure essentially free of porosity, sand, and other inclusions that can affect the endurance ratio and severely lower fatigue life. Dura-Bar® has optimal strength in tension, compression, and fatigue versus castings. Ductile irons having nodular graphite will have the highest endurance ratio, and gray irons with coarse flake graphite will have the lowest.

Hardness measures the material characteristics of strength and wear resistance and is also an indicator of machinability. The material hardness of cast iron is usually measured by Brinell Hardness Testing (BHN). This measure is easily converted to other hardness values for comparisons. It is important to use hardness as a measure of strength, wear, and machinability, but only within a particular grade. Different grades of iron or steel with the same hardness values may not be comparable in strength, wear, and machinability. The softest grade of Dura-Bar® has a hardness of 131 BHN. The maximum hardness value is 329 BHN.

Dura-Bar® cast iron has an excellent response to heat treatment. An achievable matrix hardness of 60 Rc and an average hardness of 50 Rc is possible. The severity of the quench rate must be controlled to reduce the possibility of cracking. Stress relieving may be necessary depending on the nature of the heat treatment.

The Dura-Bar® continuous casting process can supply products in near-net shapes, eliminating the need for expensive patterns or molds. This can allow for the elimination or reduction of machining versus castings and traditional bar stock. Industrial Tube & Steel stocks a full-size range and is readily available with little to no lead times.

The Dura-Bar® continuous casting process and the product's graphite properties result in faster machining (as much as 50%) and less scrap over carbon and alloy steels. The superior Machinability is possible due to the graphite in Dura-Bar® iron giving it natural chip-breaking abilities and resulting in precision machining at optimal speeds. The material being removed will either come off in long stringers or small chips, commonly known as free machining. Steel "free machining" is possible only by adding elements, such as lead, resulting in particles being present in the materials. The matrix structure is the most significant contributing factor that affects the ease of cutting and tool life. Dura-Bar® 65-45-12 ductile iron has the highest ferrite percentage in the ductile grades and is most easily machined. The G1 and G1A gray iron grades contain ferrite, making them easier to machine than G2 or G2A fully pearlitic grades. Dimensional stability depends on the machining conditions and the number of residual stresses in the as-cast bar. Most applications do not require stress relieving. Occasionally it is necessary when extremely close tolerances are required in the machined part. Material grades, by themselves, do not adversely affect the ability to hold tight dimensional tolerances, although more residual stresses result in a part when machining harder materials.

The metallurgical properties of Dura-Bar® mean better machinability resulting in little or no scrap. The Dura-Bar® continuous casting process and rigorous online and laboratory testing procedures detect any imperfections before shipment to the customer. In contrast to normal scrap rates of 10% to 40% with static iron castings, users of continuous cast bars can virtually eliminate scrap. In fact, Dura-Bar® is the only iron bar product with a Zero Defect Guarantee.

Dura-Bar's® fine-grained microstructure allows excellent surface finishes after machining. Surface finishes to 10 RMS can be achieved without secondary operations such as grinding and honing. Machined finishes of 32 RMS are typical, but single-digit values are readily obtainable. Optimal surface finishes are achieved with fine flake size. Coarse graphite flakes can lead to tearing of the material during machining resulting in a rougher finish. Slight modifications in tooling and machining conditions will correct this condition. The need for deburring is virtually eliminated. Parts are free from dross slag and other tool-wearing inclusions. The superior finish, free from sand inclusions, results in longer tool life.

Dura-Bar® irons have excellent thermal conductivity due to the presence of graphite. This is an advantage in applications such as permanent molds and glass molds where heat is cycled through a part. Coarse flake graphite in a ferritic matrix has a thermal conductivity value of approximately 2 times that of low carbon steel.

The graphite composition in Dura-Bar® gives it a much higher damping capacity than low carbon steel, cushioning vibrations as they are transmitted through a part. This ability to dampen vibrations results in a quieter product than is possible with a steel product manufactured to the same dimensional tolerances and with similar surface finishes. Dura-Bar® gray iron has at least 10 times the damping capacity of low-carbon steel and Dura-Bar® ductile iron has three times the capacity.

Dura-Bar® is excellent for many wear applications. The graphite particles in Dura-Bar® prevent friction welding which causes galling. Dura-Bar® resists galling and scuffing and will outperform heat-treated steel in a standard pin abrasion test when in the quenched and tempered or austempered condition. Additionally, localized thermal stresses are reduced because of Dura-Bar's® high thermal conductivity. Alloy additions, such as chrome, will stabilize carbides and improve wear properties if necessary.

Dura-Bar® continuous cast iron weighs 10% less than steel resulting in substantial savings in material, transportation, and delivery costs to the manufacturer. This can also be especially important when meeting requirements in applications where weight is a consideration.

Streamline your supply chain with high-quality Dura-Bar Cast Iron from Industrial Tube & Steel. As a leading metals distributor for over 65 years, we have the inventory, resources, and capabilities to meet your material needs on time and within budget.

Contact us for more information about our Dura-Bar Cast Iron.

Dura-Bar® gray iron is a good fit for a variety of applications due to its good machinability, wear resistance and vibration damping properties.

View All

Dura-Bar® ductile iron can be a cost-saving alternative for low to medium carbon steels.

View All